Built upon decades of experiences in oil field drilling and production equipment designing, engineering and manufacturing,CliftTech is oriented from an over 50 years old oil field equipment powerhouse which experienced ownerships of the governments, state owned companies as well as multinational company such as Weatherford. After Weatherford announced the closure of WFTSC plant in 2018 after ten years of ownership, the plant management team and employees started a new journey under the banner of CliftTech.

CliftTech combines cutting edge technologies with efficient supply chain to offer safe, reliable, efficient and Since making the first pumping unit in 1971, we have delivered tens of thousands of pumping units meeting not only GB requirements but also API standards. Our latest design inherited advantages from both Russian and US oriented designs and improved according to decades of oil field application feedbacks and manufacturing experiences. Instead of outsourcing to low cost suppliers to maintain cost competitiveness, we keep manufacturing in house while achieving uncompromised quality integrity and unmatchable cost efficiency by adopting L ean Six Sigma methodologies systematically. Our products are created for you to joy.

Safety: Safer installation and component handling are key factors for our updated designs.

Reliability: Based on tens of thousands of units of manufacturing, installation and application experiences, continuous improvements have been integrated into designs to ensure reliability.

Efficiency: Efficiencies are built into the design to help customers enhance production.

Sustainability: Our pumping units are built to last. One of the examples is the pumping units made back in 1980s are still running in the oil fields.

| EC | HD |

| EC320-256-120 | HD320-256-120 |

| EC456-256-120 | HD320-305-120 |

| EC456-305-168 | HD456-256-120 |

| EC456-365-120 | HD456-305-144 |

| EC640-365-168 | HD456-365-144 |

| EC912-305-168 | HD640-305-120 |

| EC912-365-168 | HD640-365-168 |

| EC912-427-192 | HD640-365-192 |

| EC1280-427-192 | HD912-305-192 |

| EC1280-427-216 | HD912-365-168 |

| HD912-427-168 | |

| HD1280-365-192 | |

| HD1824-427-216 |

DESIGN

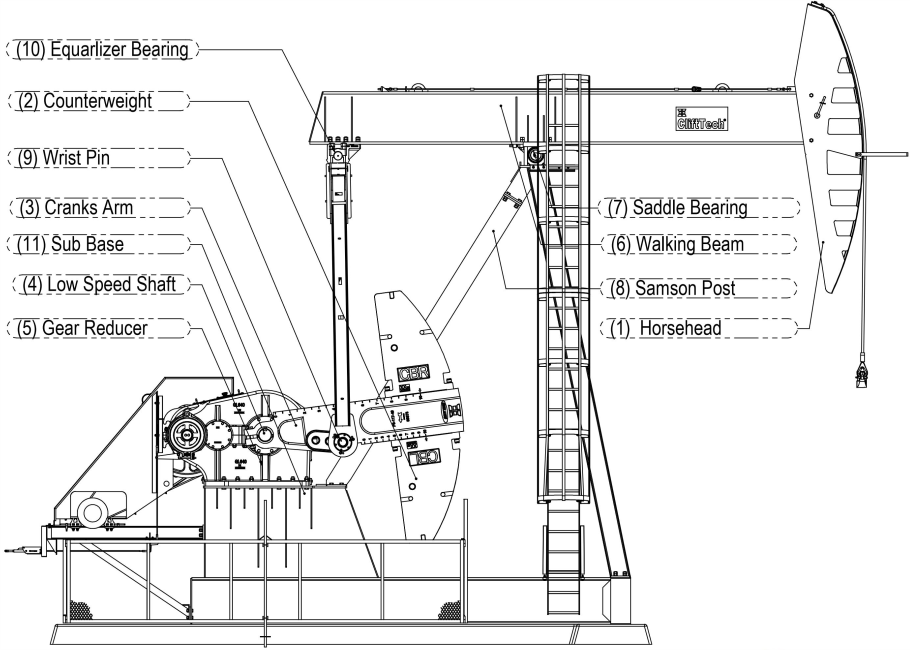

Horsehead

▼Rolled plates replaced by flat plates to mitigate cutting distortion

▼An opening at lower end of arc plate to ensure rod passing

▼Adjustable bolt for installation convieniance

Counterweights (CW)

▼L ifting hole for safer operaton

▼Super nuts for safer and more conviniant instalation

▼One piece forged T bolt to improve reliability

Cranks

▼Enhanced structure

▼Lifting hole for safety

▼Lock washer for better reliability

Crank Shaft (Conventional Units)

▼Enlarged for greater torque capacity and strength, reduced deflection and gear wear;

▼F orged alloy steel for better strength

Gear Reducer

▼L iquid level indicater for more conviniant maintaining

▼Embracing style break for safer operation

▼L ock washer for better reliability

Walking Beam (WB)

▼Tighter control on straightness of H beam to improve assembling accurace.

▼Optimized stiffeners to improve walking beam strength.

Saddle Bearings

▼AP bearings for longer service life

▼Lock washer

Samson Post

▼L ock washer applied for assured bolt torque

▼Lifting hole added for safer installation

Wrist Pin

▼Super nuts applied for reliable torque and seating

▼Optimized bearing choices for better reliability

▼Special wrench not required any more

Unit Base

▼Front and back lifting holes added for safer

installation

Tel: +86 0838-2681818

Email: sales@clifttech.com

Add: No1,Tuojiang Road West,Shlfang Sichuan,China

Mobile